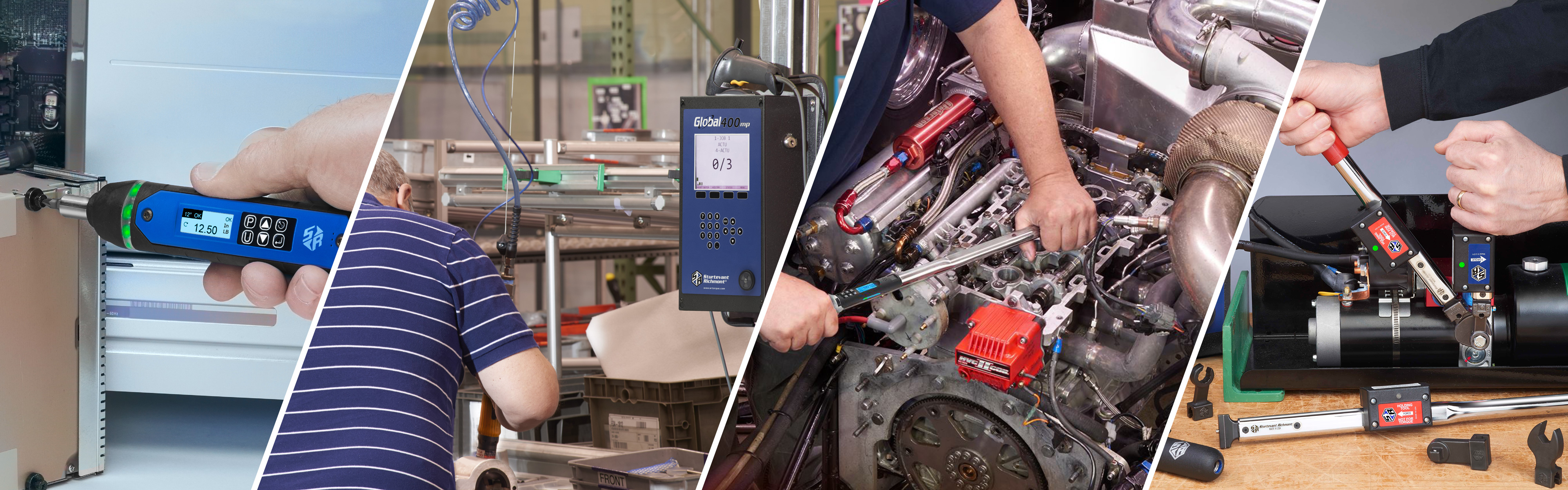

Error Proofing Solutions

We design, engineer, manufacture, and market torque tools. But our customers buy error-proofing from us. Seems odd? It isn't. The very first commercial torque wrench was the basis for the error-proofing industry. Paul Sturtevant knew that. Every tool we have designed and built since that time has had error-proofing built into it.

The concept is simple. If we don't error-proof our own tools how can you expect to fully error-proof your assembly operations? Room for error in our tools only introduces another variable into your equation. Error-proofing is about eliminating variables that cause errors. We have built error-proofing into each and every single tool in our lineup. We have systematically approached this with error proofing by design, modification, and guidance.

These three approaches all work in conjunction with each other. In some cases, there may be only one of the error-proofing approaches. In most cases, two or even all three of the error-proofing approaches find their way into a tool.

We design our tools to reduce or eliminate the human influence in the torque application and torque testing process.

Our eingineers have worked within the context of error-proofing by design. You can see the application of that concept accross our line of products. We invented the first click wrench and what makes our wrench different is the flattened case. The flattened case was designed to reduce the human influence on torque application.

Rounded beam torque wrenches are more flexible and they "sideload." In torque application and torque testing, the wrench was pulled at 90 degrees from the head. Any movement up from down from the 90 degree plane changes the torque calculation. Sideloading inhibits accuracy in the lab and on the shop floor. The flattened case prevents sideloading. When the tool is designed to eliminate human influence and errors, that is error-proofing by design.

We have worked hard to eliminate human influence in the torque application and torque testing processes. After all, humans are the largest source of mistakes in assembly because humans are the most variable component in the equation.

Our engineers have taken the next step in this with error-proofing by behavior modification. We start with the strong belief that people want to do a good job. People want to succeed and be recognized for this. Some workers want immediate and continuous feedback and error-proofing by behavior modification does just that.

Training and support are especially important with new hires. Supervisors and managers tell us that they don't always have the time to thoroughly train new associates or existing staff who may be new to some tools and tasks.

We provide the operator with feedback on each fastening. Our combination of intelligent tools and process monitor/controllers both provide visual and auditory feedback on each fastener, which gets an OK/NOK. The tools providing feedback on each fastener is error-proofing by behavior modification.

We don't stop there! We require that the operator redoes the non-conforming fastener and make it right before advancing. That is the coaching people want. They want to do a good job, and the operator gets positive reinforcement every time a fastener is conforming.

W. Edwards Deming said that people do their best and often it is the system that prevents them from doing so. Our integrated and systematic approach to error-proofing supports people in doing their best.

All assemblies require some type of operator guidance. Some are simple while some are complex. It is simple feedback letting an operator know that the fastnener is not compliant. Our guidance can come in the form of ensuring that the right tool for the job is selected, used properly, and returned to the appropriate place in the tool tray.

We believe operators demonstrate pride of craftsmanship when the obstacles to quality are removed. Our error-proofing by guidance approach removes many of those obstacles. Our goal is to help your team do the great job they want to do.

A majority of errors come outside the system. Even on the best of days, there are plenty of distractions on an assembly line or in an assembly cell. Our error-proofing by guidance has been carefully crafted to guide the operator where it is needed most. We have designed our systems to account for about everything that might happen in an assembly process where torque is involved.

We give you both flexibility and control over the error-proofing. For example, you determine whether or not the process monitor advances the batch count when a fastener is non-compliant. You can shape our system to your needs rather than our system dictating what you can and cannot do.

1. A worker with a set of wrenches and sockets

The worker has complete control over the assembly process including throughput and quality. Being totally employee dependent may not be as risky when you have a well established, experienced workforce. But what about new hires or seasonal workers? Can you control throughput and quality with a less experienced workforce?

2. A worker with a set of torque wrenches

The worker is responsible for choosing units of measure, torque values and ensuring that proper technique is used to maximize accuracy and quality. Post assembly inspection is still critical in evaluating and maintaining required quality levels because there is no documentation that the work was done properly.

3. A worker with a preset wrench

With the preset torque wrench, the worker no longer has the responsibility to select units of measure and torque values. There is no documentation that the work has been done properly. Add a switch to the torque wrench and it can be tethered to a Programmable Logic Controller (PLC) providing notification to the production system and the worker with simple OK/NOK feedback.

4. A worker with radio-equipped wireless tools

In the most basic application, paired with a simple process monitor a radio-equipped click wrench can provide OK/NOK feedback on each fastening. On the high end of the scale, a process controller can organize up to 16 tools, 100 parameters, 100 jobs, and provide the worker with a predefined assembly sequence. Responsibility for the assembly sequence is shifted to the controller and associated tools. These systems have built-in error-proofing processes to ensure quality and limit variables or workaround. The sophisticated process controllers have the ability to change parameters quickly, convey results in "real-time" or results can be stored and downloaded later. Throughput increases and the digital data documentation gives management excellent insight into as much detail as they want while still providing a broad-based view of the operation.

5. A worker or a robot with a DC Nut runner

The speed, power, control, and accuracy you get from adding DC tools come with an appropriate price. If you have the volume and the budget these solutions can provide real ROI for your assembly. There may be a trade-off. In this case, the trade-off may be the ability to access all of the fasteners and gain the control that you have with the DC tool. Wireless hand torque tools and process controllers may still play an important part of the equation if you want supervisory control and data acquisiton.

6. Total robotic assembly

The ultimate assembly solution comes at a premium price. You gain ultimate control and in exchange give up the flexibility. Ask the robot to step outside the tasks for which it was designed and your investment of resources can be stretched to the limits.

Scenaries like this (along with number 1) are the extremes in the error-proofing spectrum. While a nut runner is highly effective they typically cannot reach all fasteners. What do you do then?

By looking at which scenario best represents your current situation you can explore other options to increase throughput, cut rework, and gather required data.